|

|

|

|

|

|

User-friendly operator guidance and process

visualization.

Formulation management.

For different processes and

For different

products.

Multi-user capability.

Multitasking.

For parallel

processes.

Integration.

In networks.

In

higher-level systems.

Compliant with 21 CFR Part 11.

Customized

solutions.

Based on globally established standards.

Ex design.

Optional. |

| |

| |

|

|

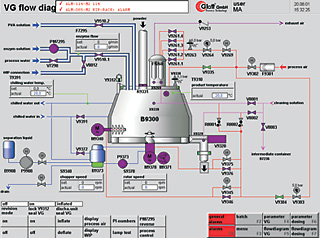

User-friendly operator guidance and process visualization

The process sequences can be freely configured and can run manually,

semi-automatically or fully automatically. The Glatt PC-based MegaView provides

logical operator guidance and a comprehensive and clear visualization of the

process on a large-screen TFT monitor for:

Machine control screens

Process schematic with display of functions

Graphical display of process parameters

Formulation management

Operator guidance

Of course, all necessary safety-related interlocks are incorporated.

|

|

|

Process visualization:

Process visualization:

Drum coating |

Glatt MegaView control

Glatt MegaView control

panel Alternative 1 |

|

|

|

Multitasking for parallel processes

Machines connected to the system (e.g. a vertical granulator, a fluid bed

granulator and a WIP rack) can be operated from a central control system. The

control system can be equipped with one or more control panels on request.

|

|

|

Integration into networks and higher-level systems

The Glatt MegaView provides all interfaces for integration into networks and

higher-level systems such as an MES (Manufacturing Execution

System). This allows the control, monitoring and documentation of

complete production processes to be fully automated. Production data can be

documented and evaluated centrally (->

Process Control Systems).

|

|

|

Compliant with 21 CFR Part 11

Measurements can be recorded, processed and stored electronically. Connection

to databases, electronic records (ER), electronic signatures (ES) or audit trail

- the Glatt MegaView fulfills the requirements of the FDA Directive 21 CFR Part

11. And of course, if you wish, we will be pleased to provide you with

comprehensive documentation on our control systems for Validation, Qualification and Calibration - right up to GAMP 4.

|

|

|

Customized solutions

In order to fulfill customer-specific requirements to the greatest possible

extent, we develop and implement our own control systems for our

machines.

Globally established software and hardware form the basis of

these.

The standard PLC is Siemens. We can also supply Allen Bradley or other

makes on request.

|

| |

Control cabinet |

| |

|

| |

Process visualization: Vertical granulator |

| |

Ex design

Glatt MegaView can be supplied in a pressurized design for use in Ex-Zone 1

or 2 (protection class EEx(p)).

|